Why Lean Six Sigma matters?

- Antonella

- Oct 4, 2021

- 4 min read

Updated: Dec 16, 2021

When Lean Six Sigma methodology is used correctly in a company, there is an increase in revenue, decrease in costs, and a healthy backlog of work.

We can consider ourselves all customers and as customers we always want to do business with reputable companies. To satisfy our criteria for selecting a company to do business, we look at the quality of the products and the value we are paying. Take Amazon as an example. You will go to the website, search for what you are looking for and look at the price and reviews. You’re not going to select something that costs less but has bad reviews. You are going to make an educated decision based on the information you have. The more reputable the company is, the greater the number of reviews it has on their product. Thus, chances are that behind the product you are looking at, there is a company that strategically aligned themselves to their market base and includes continuous improvement (CI) philosophy in their DNA. These are companies with a long-term vision and mission statement, which include quality-based methodologies like Lean, Six Sigma, or both, and are learning from their mistakes.

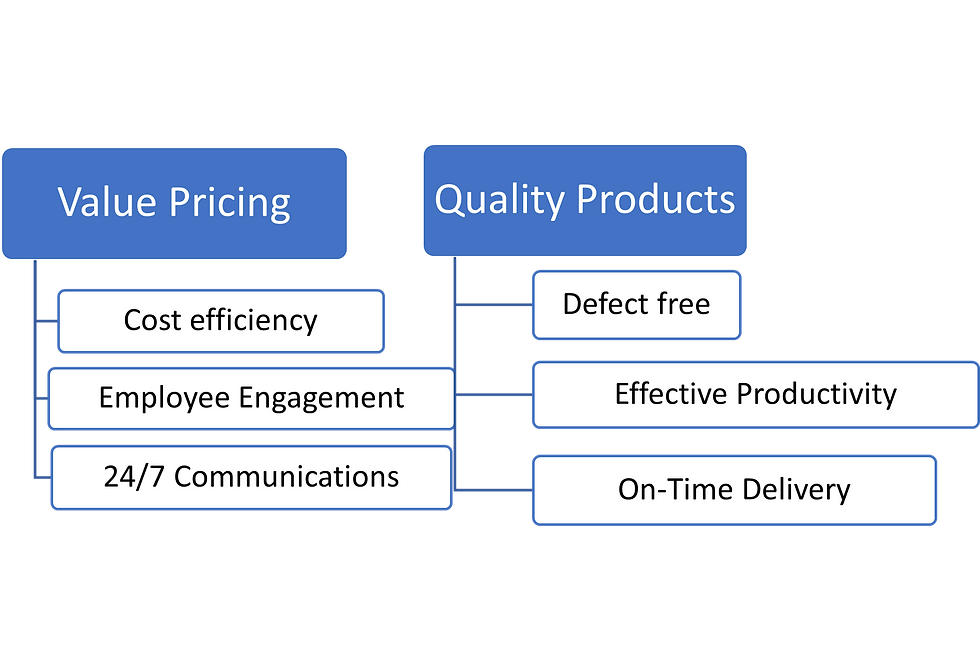

Let us zoom into the quality products and value pricing. When it comes to value pricing, you can still make money as a company if you have a cost-effective way of producing the product;

your employees are happy and engaged to innovate; you can service your customers at any time. To have quality products, as a company, you need to make sure there are no defects in the product, you can produce it effectively and it’s sent to the customer in a timely matter. These items make up the benefits of applying Lean Six Sigma in your business.

The Lean philosophy is all about seeing waste. It deals with non-value-added work being reduced or removed in order to work effectively in a one-piece flow. The Six Sigma philosophy uses statistical analysis to identify variation. It uses your process’ data to better understand its capability and zoom into the real causes for the variation so as to reduce or remove it.

Sadly, many companies choose to use one of the two philosophies, handicapping their business. Why is it important both philosophies are used in a company? Take the office environment where the customer service group is responding to customer requests both by phone and email. To identify the wastes, you would go see how the customer service representatives are working, record every step they make, and then map it out to get a visual view. If there are over ten representatives at your company, it will take time for you to watch each one and record what they are doing. Furthermore, the day you are observing does not guarantee you will be able to see all the types of requests coming in. Do you spend the next month observing the representatives? Chances are, the answer is no, because the more time you are observing the less time you are doing your tasks for the day. Time is money! This is where statistics become important. You retrieve from your database the type of customer requests coming in when they are opened and when they are closed out. You figure out which type of requests take the longest time to close as well as the ones that occur frequently. The results from the stats will guide you to observe the request types with the most variation. This will limit the time you are looking for waste.

On the other hand, if you are in the manufacturing environment, you can be looking at a particular machine which is producing a lot of scrap materials. Something is making the machine cut some rods at a slight angle. You go check the machine. It’s calibrated and the correct recipe is applied by the operator. Next you observe how the operator is placing each rod to be cut on the machine. He seems to be repeating each step identically. You decide to observe for another hour, but nothing happens. All the rods being cut are to specification. You go back to your office to work. Some time passes and you get a call from the operator. The issue is back, and more rods have been scrapped. You’re baffled! Going back to the cutting machine, you find that the rods coming out of the machine are back at being to specification. What is going on? You can’t just spend all your time in front of the machine, waiting for it to fail. Also, the errors cannot be reproduced because the operator is also baffled with what is happening as well. You finally decide to get data from the operator so you can analyze the problem. The stats show you that the machine is out of control at the start of the shift as well as at lunchtime and three in the afternoon. You decide to go observe at these times and find that when the machine goes from idle mode to working, it creates scrapped materials. Every time the operator takes a break, this happens. Now you know you need to have the machine warm up before producing parts.

The two philosophies complement each other which is why they are combined in one methodology. To learn more about how to bring your company to the next level, contact us to schedule a free consultation call.

Want to learn more? Click on our Leadership series or our Inspirational stories (Anna & Dude series).

Let us know what you think with your comments….

Comments